We are happy to announce the launch of our new mobile container treatment plant solution. It enables our customers to test our products with the relevant type of wastewater, which gives them the opportunity to compare and determine the best solution before deciding and investing.

Based on a design & engineering concept by MUTAG, we have developed a mobile container treatment plant solution in close cooperation with the company Wastewater Solutions Group GmbH from Bachmanning, Austria.

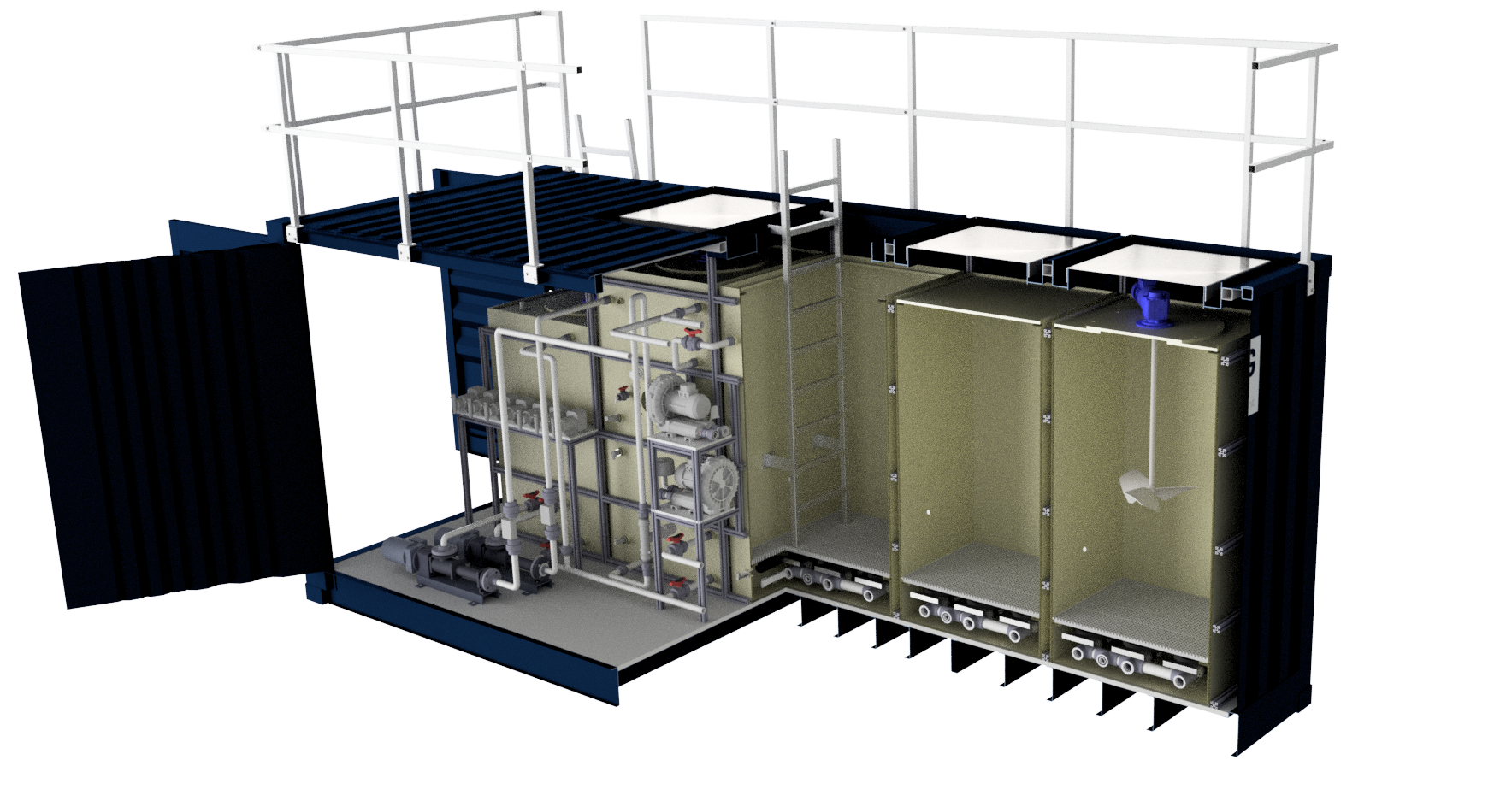

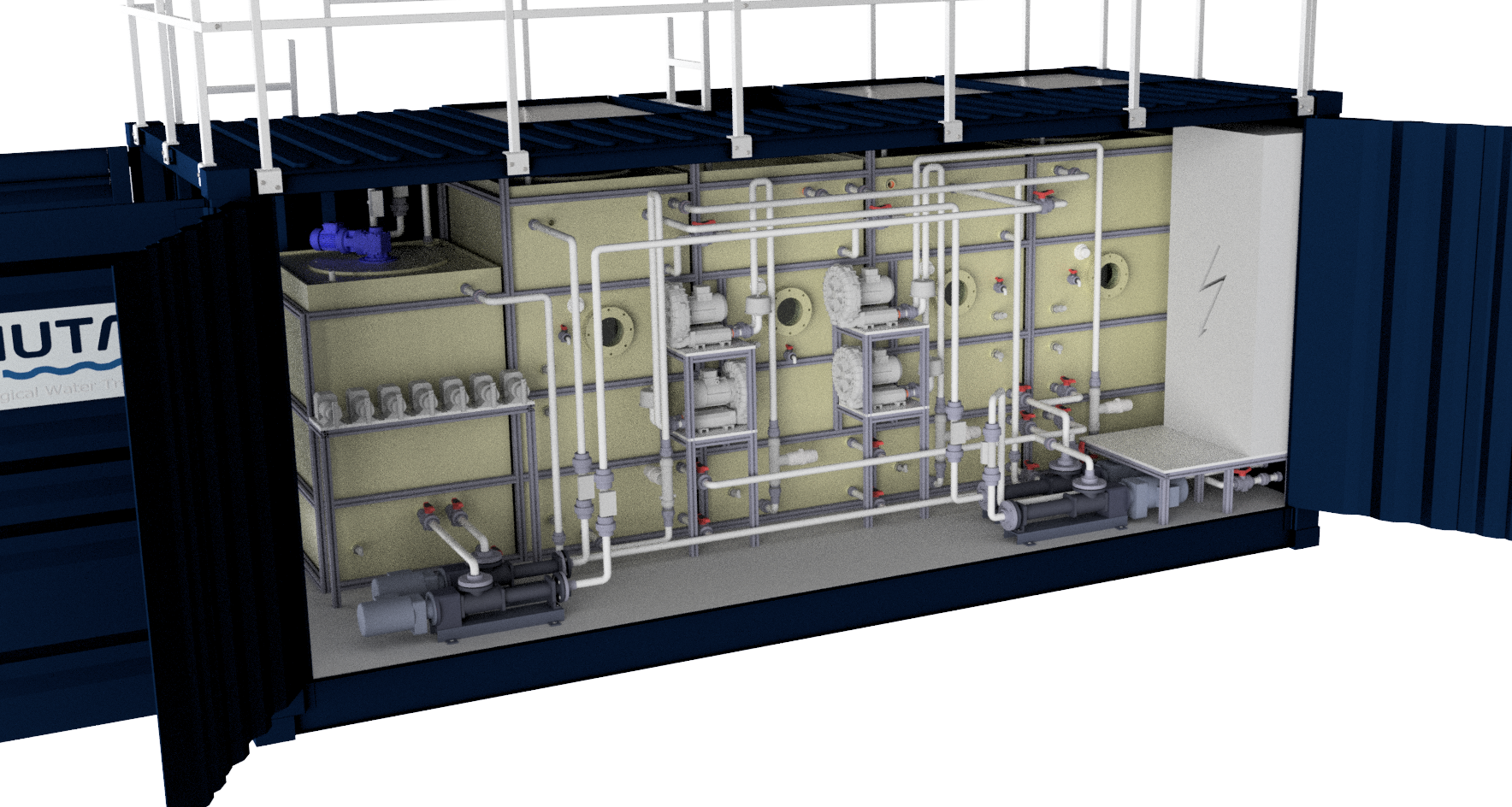

The plant is housed in a 20ft container and is consisting of four reaction tanks. It is also equipped with an equalization tank, agitators, aeration systems, pumps, as well as a variety of regulation, measurement and control technology in order to treat the widest possible range of wastewaters.

The range of applications extends over the entire field of wastewater treatment, so in addition to industrial effluents, it is also intended to be used for municipal wastewater as well as in the in the field of aquaculture.

A submersible pump is used to extract a partial flow from an existing wastewater system and to feed it to the equalization tank. There, the wastewater flow is being equalized and fed to the reaction tanks via eccentric pumps. Depending on the application, up to four tanks can be used to carry out both aerobic and anaerobic treatment. Furthermore, depending on the main focus and wastewater composition, a nitrate return can also be carried out to ensure the necessary degradation of nitrogen compounds in the upstream denitrification.

Optionally, parallel treatment can also be carried out which is particularly useful when it comes to determining the influence of individual parameters on the treatment quality, as an identical wastewater can be treated simultaneously under different conditions.

Basically, new process concepts are to be tested in order to have a reliable data basis for a later scaling of the process. At the same time it will be tested whether and to what extent biological treatment of the wastewater is possible.

In this way customized solutions can be developed and tested in order to carry out a precise dimensioning of the required components.

FOR CUSTOMERS ALL OVER THE WORLD

As this is a mobile plant, the piloting can be carried out anywhere in the world; only a suitable site and the necessary process chemicals are required on the part of the customer.

In addition to testing new process variants, it is also possible to vary the existing process parameters without affecting the overall process, thus ensuring significantly greater flexibility with constant process reliability.

We are very excited to offer this new possibility to our customers. If you would like to know more about our new solution, please do not hesitate to contact us.